Type:

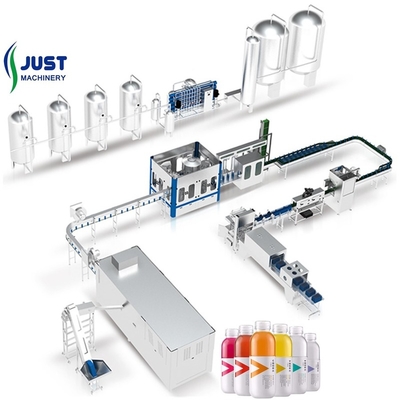

Filling Machine

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory

Showroom Location:

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sr

Condition:

New

Application:

Beverage, Food

Packaging Type:

Bottles, CANS

Packaging Material:

Plastic, Wood

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

220V/380V/415V/480V 3P

Dimension(L*W*H):

2900mmx2100mmx2200mm

Weight:

4500 KG

Warranty:

5 Years, 5 Years

Key Selling Points:

Long Service Life

Machinery Capacity:

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH, 1000-30000 Bph

Filling Material:

Water, Juice

Filling Accuracy:

± 0.5 Mm

Marketing Type:

New Product 2021

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

More Than 5 Years

Core Components:

Motor, Pump, PLC, Gear

Name:

750ml Hot Filling Machine

Key Words:

Juice Beverage 750ml Hot Filling Machine

Function:

Automatic Juice Beverage 750ml Hot Filling Machine

Bottle Size:

150-2000ML

Capacity:

1000-30000bph

Material:

Stainless Steel 304/316

Bottle Type:

PET Plastic Bottle

Feature:

Automachine

Control:

PLC+ Touch Screen+transducer

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!