Type:

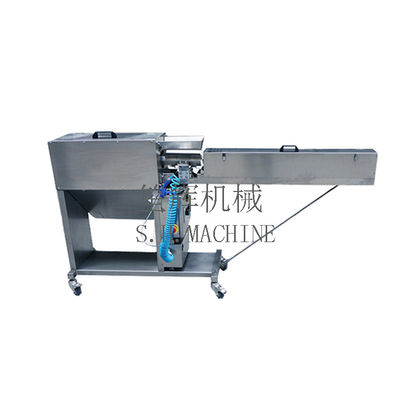

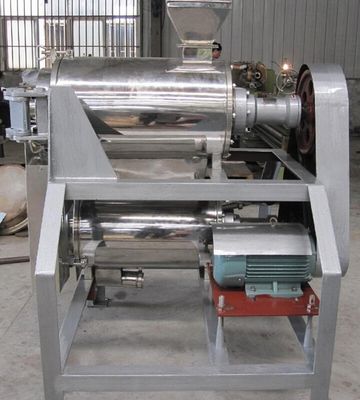

Multi-Function Packaging Machine

Applicable Industries:

Manufacturing Plant, Machinery Repair Shops, Farms, Retail, Food Shop, Food & Beverage Shops, Advertising Company

Weight (KG):

200

Showroom Location:

Canada, United Kingdom, United States, Germany, Philippines, Malaysia, Australia

Condition:

New

Function:

FILLING, Labeling, Sealing

Application:

Food, Medical, Machinery & Hardware, Tobacco

Packaging Type:

Stand-up Pouch, Bags, Film, Pouch

Packaging Material:

Plastic, Wood

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

220V

Dimension(L*W*H):

(L)2000mm*(W)1630mm*(H)2200mm

Warranty:

1 Year

Key Selling Points:

Automatic

Marketing Type:

Hot Product 2019

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Motor, Pressure Vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

Production Capacity:

25bag/min, 15bag/min, 30bag/min

After-sales Service Provided:

Engineers Available To Service Machinery Overseas

Machine Material:

SS#304 Or Carbon/Mild Steel

Film Changeover:

Simple And Fast Bag Sizes With One Set Of Formint Tubes

Controller System:

PLC And Touch Screen With Simple Manu-based Interface

Software Operation:

Program Storage And Retrieval Function

Bags Or Products Changeover:

Parameters Setting On The Touch Screen

Bag Sealing:

Indepedant Temperature Adjustment

Film Pulling:

Panasonic Servo Motor Driven System

Horizontal Sealing Jaws:

Panasonic Servo Motor Or Air Cylinders Driven

Film Installation:

Electrical Shaft With Brake Function

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!