Applicable Industries:

Machinery Repair Shops, Food & Beverage Factory, Construction Works , Energy & Mining, Wastewater Treatment

Showroom Location:

None

Video Outgoing-inspection:

Provided

Machinery Test Report:

Not Available

Marketing Type:

New Product 2020

Warranty Of Core Components:

3 Months

Core Components:

PLC, Motor, Filter Press

Condition:

New

Automatic Grade:

Automatic

Voltage:

220V/380V/400V/415V Etc

Power:

5.5KW

Weight:

9680KGS

Dimension(L*W*H):

6705*1850*1565mm

Warranty:

1 Year Excluding Spare Parts

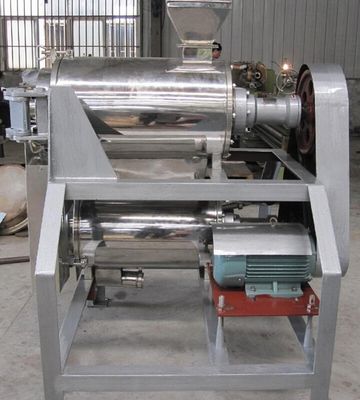

Name:

Automatic Chamber Filter Press

Application:

Solid-liquid Separation, Sewage Treatment

Filter Area:

150m2

Thickness Of Filter Plate:

30mm

Filter Plate Size:

1250*1250mm

Filter Chamber Volume:

2310L

Quantity Of Filter Plate:

55pcs

Material Of Filter Plate:

PP, Durable

Advantage:

Automatic Plate Shifting System

Filtering Pressure:

0.6Mpa

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

United States, Russia, Kazakhstan

After-sales Service Provided:

Field Installation, Commissioning And Training

Certification:

CE, ISO9001

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!